Pre-hardened Mold Steel

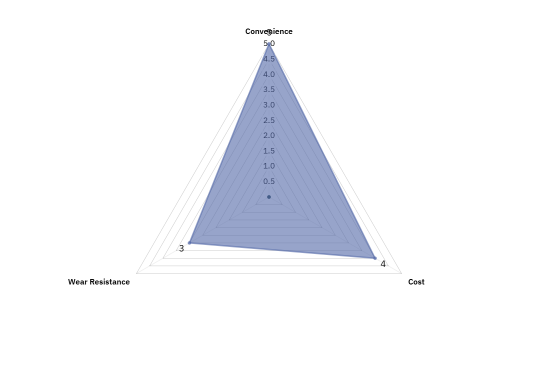

Pre-hardened is steel that’s already been hardened before leaving the factory. Its hardness meets usage requirements (in general), thus it can be used directly in mold machining & production without the need for additional heat treatment.

The main advantage is convenience, as it saves on production time & costs by reducing the risk of distortion during heat treatment. Pre-hardened steel is typically used for shorter production cycles and smaller batches, or when the mold size makes heat treatment impractical.

Common grades of this type of steel include: P20, 718/718H/718HH, 738H, NAK80, S136H, and 2083H.

Hardness (HRC): 28-32, Mod = 31-42, HH & LQ = 36-42, +S = 29-35, +Ni = 29-42

Sub-Variants*: P20 Modified, P20 HH, P20 LQ, P20 + S, P20 + Ni

Medium carbon Cr-Mo series plastic mold steel. Excellent processing and polishing performance. Affordable, HH variant is quite commonly used as an all-purpose plastic mold steel; also used for high quality mold inserts. Best suited for molding PA, POM, PS, PE, PP, and ABS plastics.

Hardness (HRC): S = 31-36, H = 34-38, HH = 36-40

Sub-Variants*: 718S, 718H, 718HH

Cr-Ni-Mo series mold steel, it's an improved version of P20 with better hardening, capable of making larger molds. It also lasts about 2-3 times longer than P20.

Also used for high quality mold inserts, well suited for molding PA, POM, PS, PE, PP, and ABS plastics.

Hardness (HRC): 29-35 (Some recommend 48-52), H = 36-42

Sub-Variants*: 738H

Has higher Mn, Cr, Ni contents than 718, with good harden-ability and toughness. Used in molds where high toughness and good finishing are desired.

Hardness (HRC): 37-43

Steel with Ni-Al-Cu added. It's machine-able, has a good electrical discharge machining performance, and excellent weld-ability. If gas nitrite is applied on the surface the hardness can reach 750HV, giving it an extra long mold life.

It's often used for molds that require a high resistance to wear, and excellent surface finishing.

Hardness (HRC): 48-52, H = 30-36

Sub-Variants*: S138H, S138 SUP, S138H SUP.

It has a high resistance to corrosion due to a chromium content of 13.6%, and features a pure and fine structure. It also features an excellent polishing performance, wear resistance, machine-ability, and good dimensional stability during hardening.

136 is often used for high quality mold inserts that require a mirror finish with a good corrosion resistance.

It's best suited for PVC, PP, EP, PC, PMMA, and machine parts for food processing machinery.

Hardness (HRC): 50-54, H = 29-35

Sub-Variants*: 2083H

Steel with a chromium content of 12.5-14.5%. It possesses a good resistance to corrosion and wear. It's got good harden-ability, and machine-ability for plastic mold steel.

Mostly used for corrosion resistant plastic molds.

Through-Hardened Mold Steel

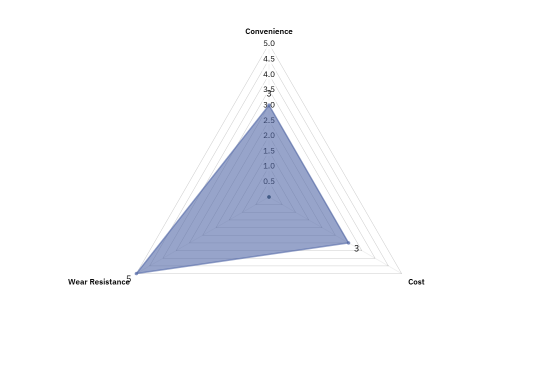

Through-hardened steel is supplied in a softened state and requires heat treatment to achieve the desired hardness. The hardness of this steel can be precisely controlled through heat treatment, resulting in higher wear resistance and toughness.

Hardened mold steel is suitable for molds that need to operate long periods and withstand high wear, especially in mass production of identical plastic parts. However, the need for post-production heat treatment can increase production costs and requires careful handling to prevent deformation and stress issues due to uneven heating or cooling.

Regular grades of through-hardened mold steels are: 2083, S136, H13, SKD61, 8407, D2, P6, and SKD11.

Hardness (HRC): 50-54

It contains Cr-Mo-V, and it's the corresponding grade to 8407. Has good wear resistance, toughness, polish-ability, and a high temperature strength, along with all the other traits from 8407.

Best suited for hard plastic molds, sliders, and zinc die casting dies.

Hardness (HRC): 50-54

Yet another corresponding grade with 8407, but with Si in it (Si-Cr-Mo-V).

It has good hardening properties, good resistance to thermal shock and fatigue, while also having a good resistance to heat erosion.

Often used in small size AL die casting molds, parts for casting molds, die extrusion molds, and hard plastic molds.

Hardness (HRC): 48-52

Features a good resistance to wear, has good toughness, and ductility. It's also very polish-able, has a high temp strength and good thermal fatigue resistance to boot. Contains Cr-Mo-V hot work alloy steel.

It hardens well, and sees minimal deformation under heat treatment.

8407 is used for die casting, and extrusions. It's a solid mold for PA, POM, PS, PE, EP plastics.

Hardness (HRC): 50-52

SKD11 is a tough chromium cold work tool steel. Its high temperature tempering post heat treatment can reach 62HRC. It's especially good for wire cut EDM to reduce breakage.

Quite suitable for stamping die, cold forming, thread rolling, punches for high speed blanking, and stainless steel materials.

*Please note that the lists above don’t cover all the available types of steels, as well as their names. Different suppliers also have different names for the same types of steel, which would only make the list longer. This also doesn’t include the sub-types of each steel, for example P20 has several alone, like P20 Mod, P20 + S, P20 + N, just to mention a few. We highly recommend contacting us if you’re not sure which type suits your needs best, we’ll be more than happy to help you choose the best type for your use case.