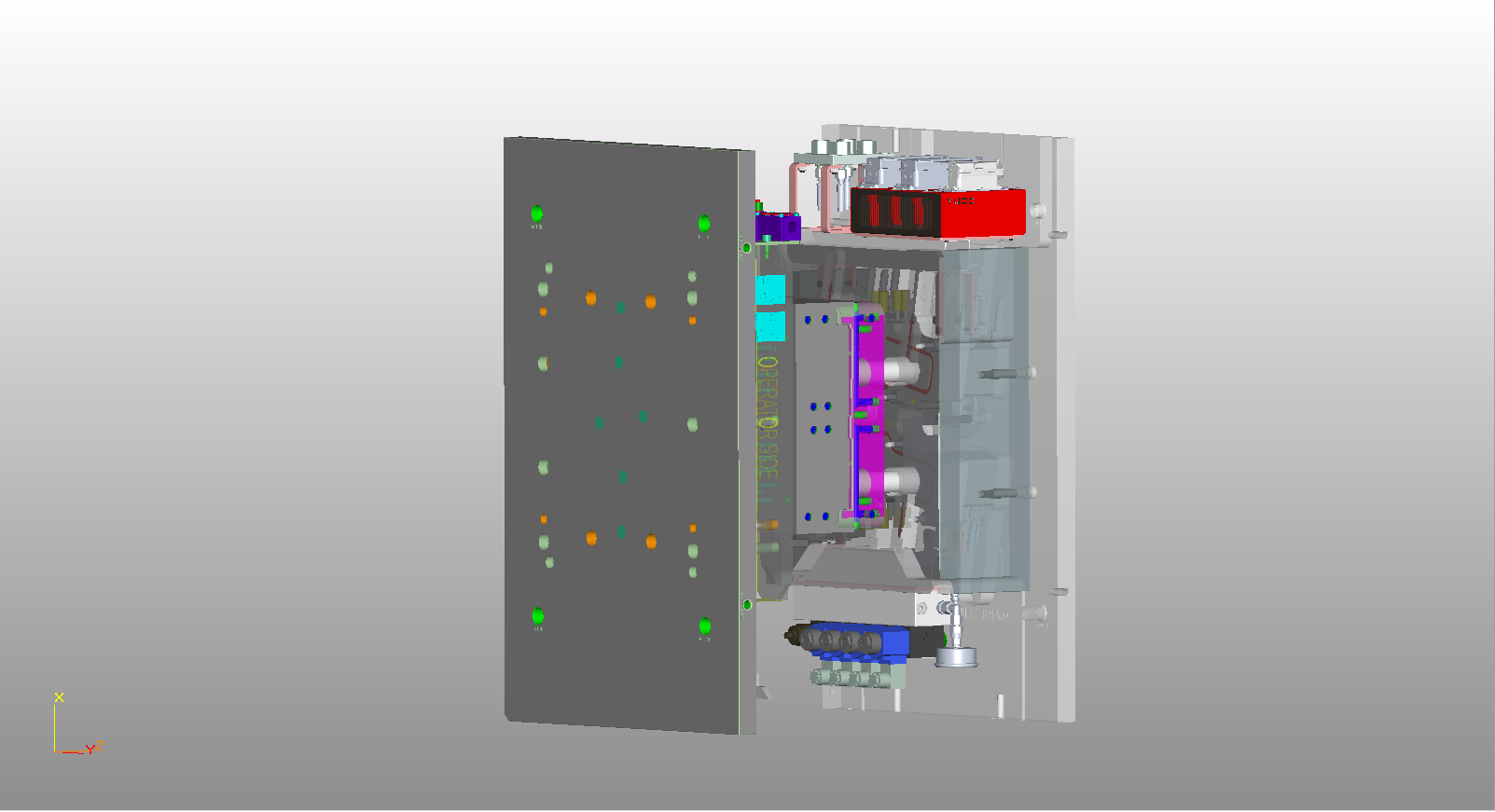

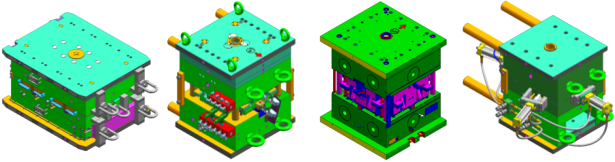

D&T uses Siemen’s Xcelerator for general design and design checks, ensuring software compatibility by maintaining to the industry standard.

One of the most important aspects of the part design process is design for manufacturing (DFM). A good place to start, as with most things in life, is Wikipedia. It defines DFM as “the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase, which is the least expensive phase in which to address them.”

Text credit – Protolabs

Essentially, we can take your existing (or roughly drafted) design, help you improve on it by removing inefficiencies, and help you reduce overall costs by spotting errors or potential points of failure earlier during the design phase rather than during the testing or production phase.

We have several designers in-house ready to assist you with the design process, and they’ll assist you with the following: